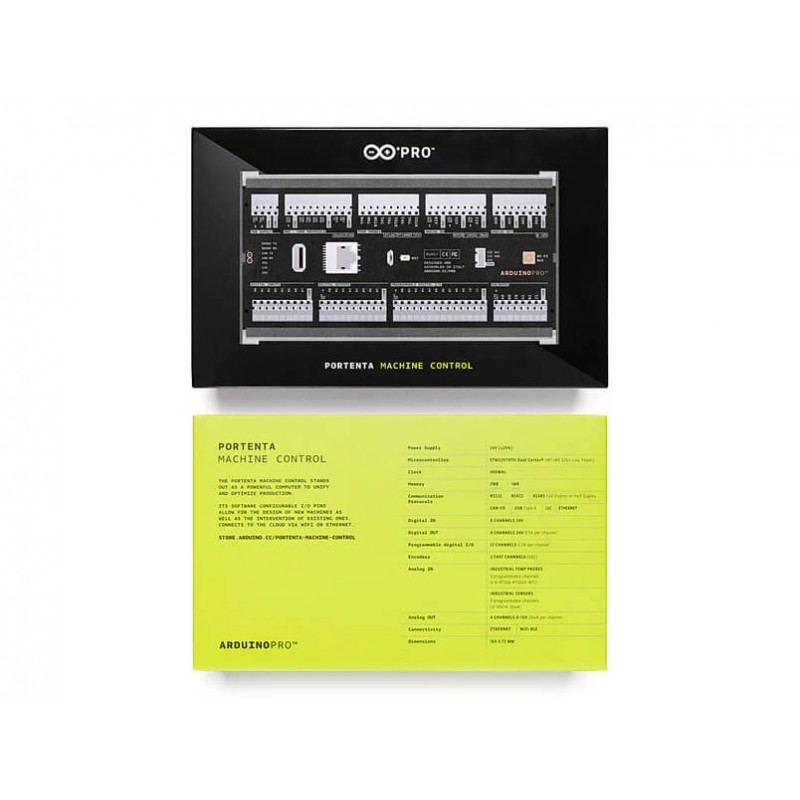

Arduino Portenta Machine Control

Cet outil est un support polyvalent et pratique pour l'apprentissage pratique dans le domaine de l'automatisation, de l'IoT et de la technologie industrielle. Grâce à sa conception robuste, il est parfaitement adapté pour apprendre aux étudiants à utiliser et à surveiller des machines. Avec des fonctionnalités telles que le traitement des données en temps réel, diverses options de connectivité et la prise en charge de la programmation avancée, cette unité de contrôle comble efficacement le fossé entre les connaissances théoriques et les applications pratiques. Les enseignants peuvent l'utiliser pour illustrer des concepts clés en robotique, en systèmes intelligents et en automatisation industrielle, préparant ainsi les étudiants à une carrière dans l'ingénierie et la technologie.

The Portenta Machine Control enables industry standard soft-PLC control and is able to connect to a range of external sensors and actuators with isolated digital I/O, 4-20mA compatible analog I/O, 3 configurable temperature channels, and a dedicated I2C connector. Multiple choices are available for network connectivity, including USB, Ethernet, and WiFi/Bluetooth® Low Energy in addition to industry specific protocols such as RS485. All I/O are protected by resettable fuses and onboard power management has been engineered to ensure maximum reliability in harsh environments.

The Portenta Machine Control core runs a Portenta H7 microcontroller board (included), a highly reliable design operating at industrial temperature ranges (-40 °C to +85 °C) with a dual-core architecture that doesn’t require any external cooling. The main processor offers the possibility of connecting external Human Machine Interfaces like displays, touch panels, keyboards, joysticks, and mice to enable on-site reconfiguration of state machines and direct manipulation of processes.

The Portenta Machine Control’s design addresses a large variety of use scenarios. It is possible to configure a selection of the I/O pins via software. The Portenta Machine Control stands out as a powerful computer to unify and optimize production where one single type of hardware can serve all of your needs. Among other outstanding features are the following:

- Industrial performance leveraging the power of Portenta boards

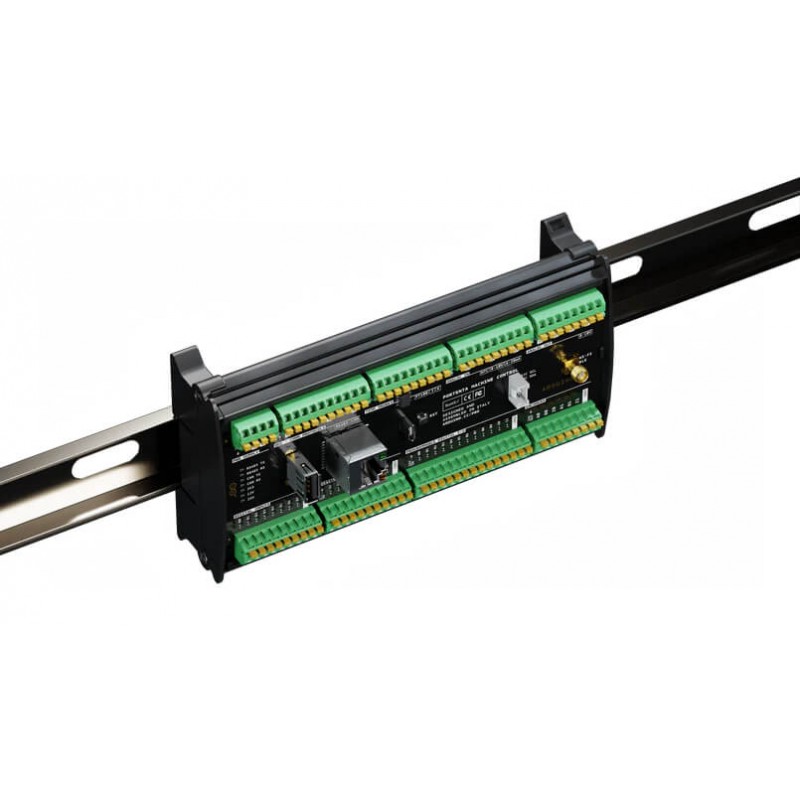

- DIN bar compatible housing

- Push-in terminals for fast connection

- Compact device (170 x 90x 50 mm)

- Reliable design, operating at industrial temperature rates (-40 °C to +85 °C) with a dual-core architecture that doesn’t require any external cooling

- Embedded RTC (Real Time Clock) to ensure perfect synchronization of processes

- Leverage the embedded connectivity without any external parts

- CE, FCC, and RoHS certified

The Portenta Machine Control can be used in multiple industries, across a wide range of machine types, including: labelling machine, form & seal machine, cartoning machine, gluing machine, electric oven, industrial washer & dryers, mixers, etc.

Tech specs

- Processor STM32H747XI dual Cortex®-M7+M4 32 bit low power Arm® MCU (Portenta H7)

- Input 8 digital 24Vdc; 2 channels encoder readings; 3 Analog for PT100/J/K temperature probes (3-wire cable with compensation ); 3 Analog input (4-20mA/ 0-10V/NTC 10K)

- Output 8 digital 24Vdc up to 0,5A (short circuit protection); 4 analog 0-10V (up to 20mA output per channel)

- Other I/O 12 programmable digital I/O (24V logic)

- Communication Protocols CAN-BUS; Programmable Serial port 232/422/485

- Connectivity Ethernet; USB Programming Port; Wi-Fi; Bluetooth® Low Energy

- Memory 16 MB onboard Flash memory; 8MB SDRAM

- Dimensions 170 x 90 x 50 mm

- Weight 186 gr

- Power 24V DC +/- 20%

- Connector Type Push-in terminals for fast connection

- Operating Temperature -40° C to +85° C (-40° F to 185°F)